Space Solutions

Insulated Panel Features and Construction

Insulated panels are fundamental to building cold storage spaces, cleanrooms, and secure and reliable spaces.

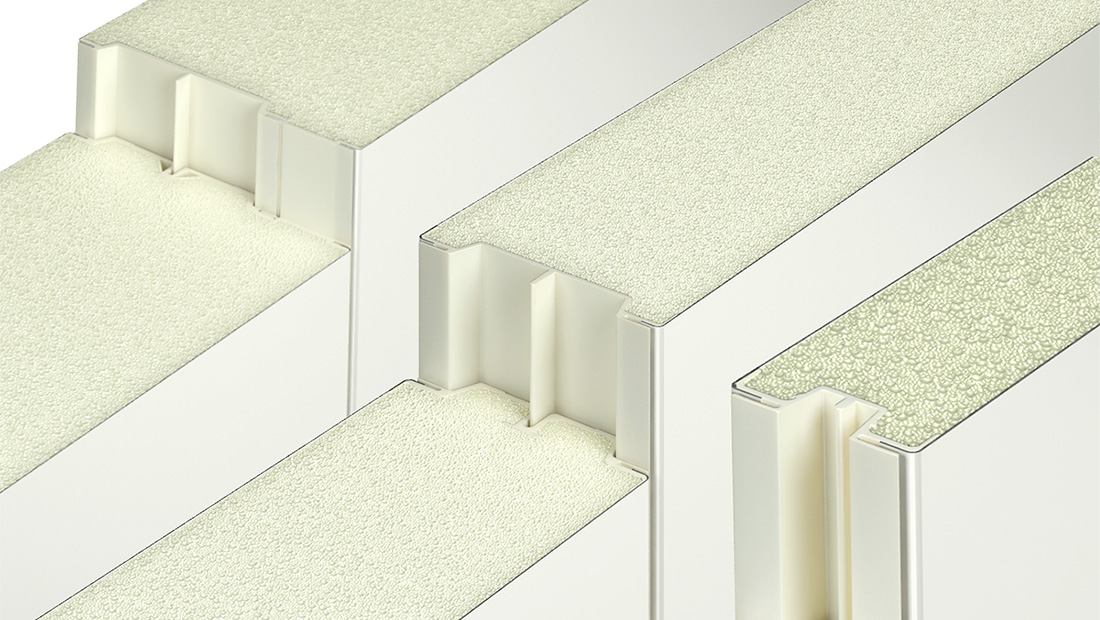

Combining panels enables flexible, low-cost space construction.

Nikkei Panel System Insulated Panel Features

Insulating and flame resistant

Flexible layout

Dust resistant and airtight

Earthquake resistant and durable

Can be combined with other products

Environmentally friendly (zero fluorocarbons)

Easy to clean and maintain

Low-cost space creation

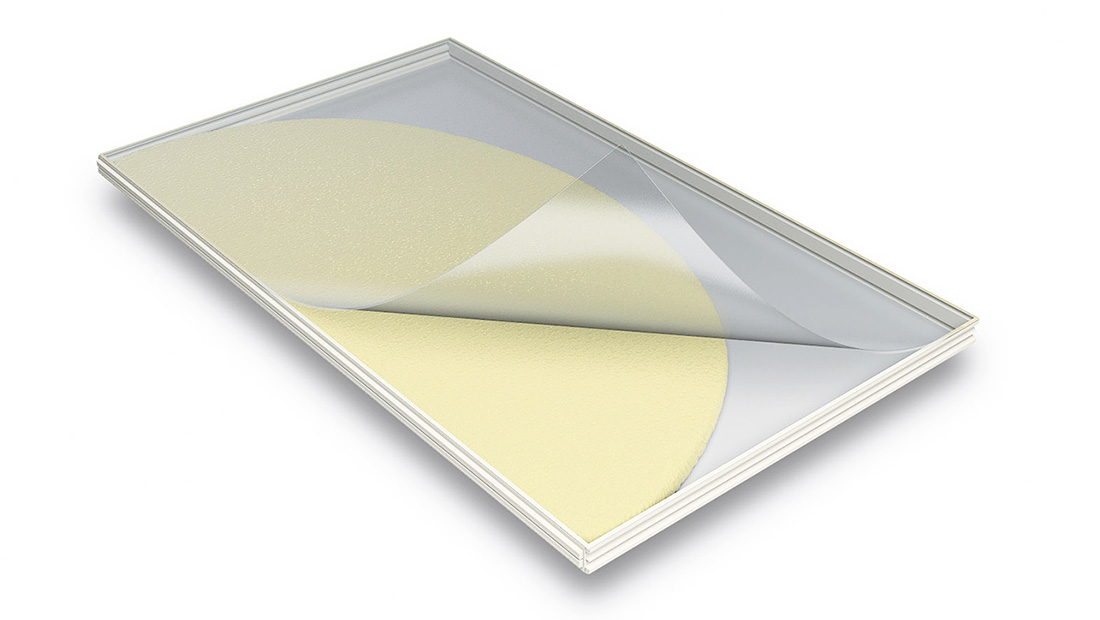

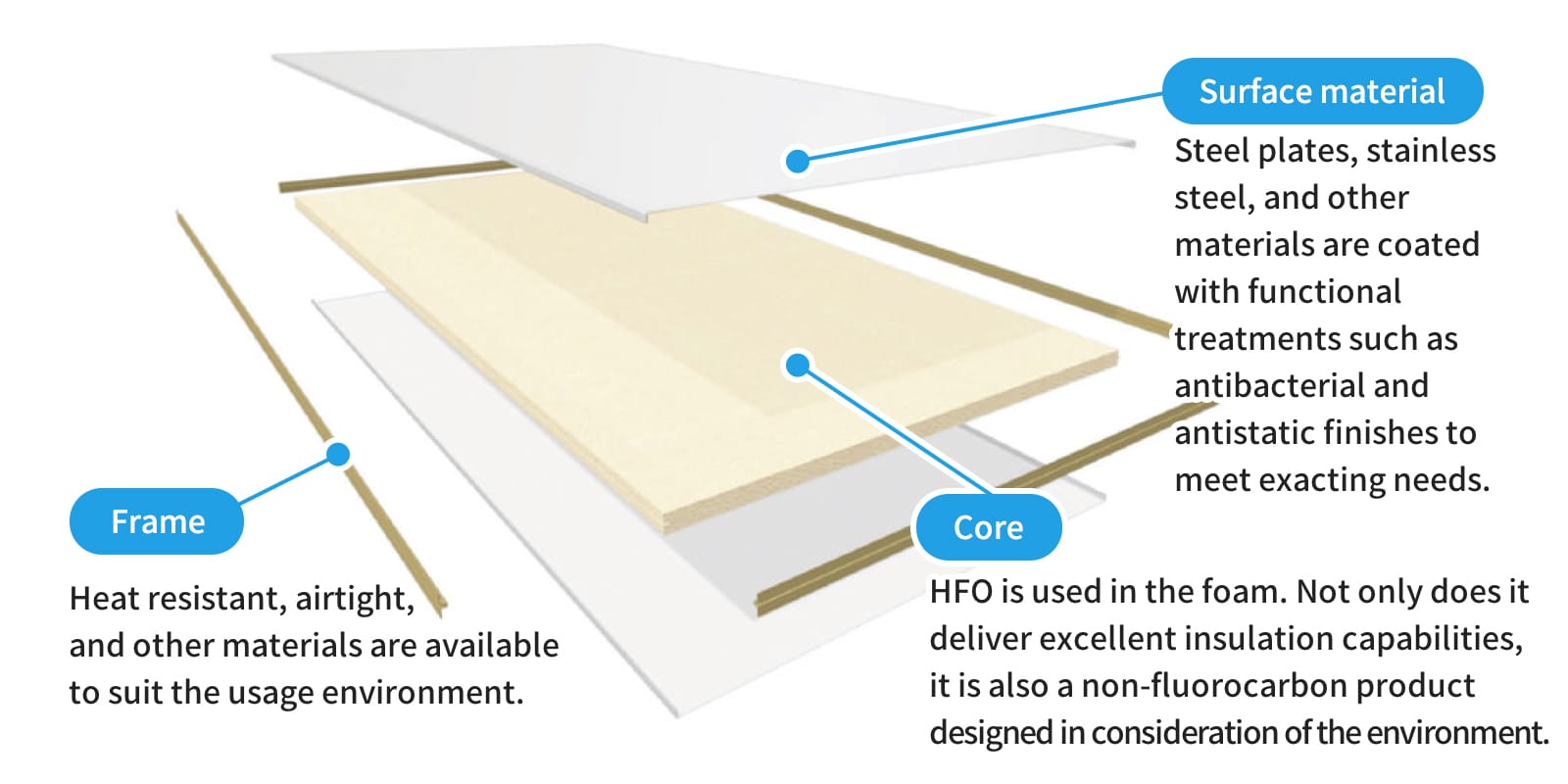

Nikkei Panel System Insulated Panel Construction

Surface material

Steel plates, stainless steel, and other materials are coated with functional treatments such as antibacterial and antistatic finishes.

Surfaces can be chosen for clean environments or to match your intended use, including wear resistance, shock resistance, and workability. The main surface of panels is colored steel plate (Two standard colors: whitish gray and ivory). Stainless steel is often used in kitchens, etc.

Core

The rigid urethane foam used in panel cores is a plastic foam created by simultaneously mixing polyol, isocyanate, a catalyst (amine compound), and a foaming agent to trigger a foaming reaction and resinification reaction at the same time. It looks like an aggregate of small bubbles. The small, rigid bubbles are individual pockets filled with gas that inhibits the transmission of heat.

Frame

Materials can be combined to achieve heat resistance, airtightness, etc., to suit the usage environment.